This is our second oldest field of activity, where we have developed our production from the original simpler products (which of course we provide today as well) to a stable, highly specialized group that can, based on customer requirements, design a construction draft of more complex devices using the latest version of a modern 3D CAD SolidWorks.

The machines designed by our company also have their own control software defined by the customer (mostly the Siemens PLC).

Manufacture, installation and wiring are provided internally thanks to a fully-functional team and fully equipped toolroom.

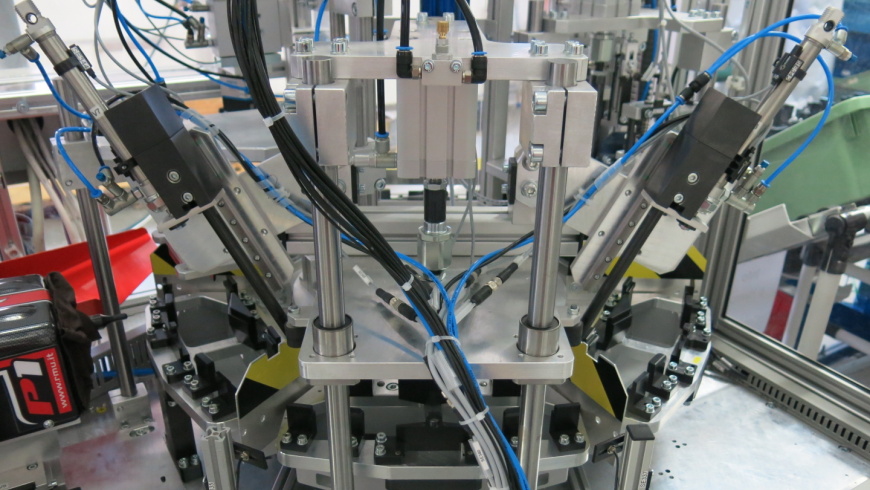

The machines are implemented with both pneumatic as well as electric drives. If a customer requests, we are able to integrate additional machine units: warm-up, caulking, riveting, screwing, labeling, gluing, greasing.

The contract also includes an internal customer acceptance of the equipment and its subsequent installation and putting into operation at the customer’s place, including staff training.

When handing over the equipment, the customer receives documentation with instructions for operation and maintenance. Warranty and post-warranty services are also provided.